Monitoring system for vehicle-integrated photovoltaics

Researchers in Slovenia have built a monitoring system for vehicle-integrated photovoltaics consisting of an IV curve scanner that uses a MOSFET as a voltage-controlled electronic load. The system also utilizes an 18-bit analog-to-digital converter and a microchip microcontroller.

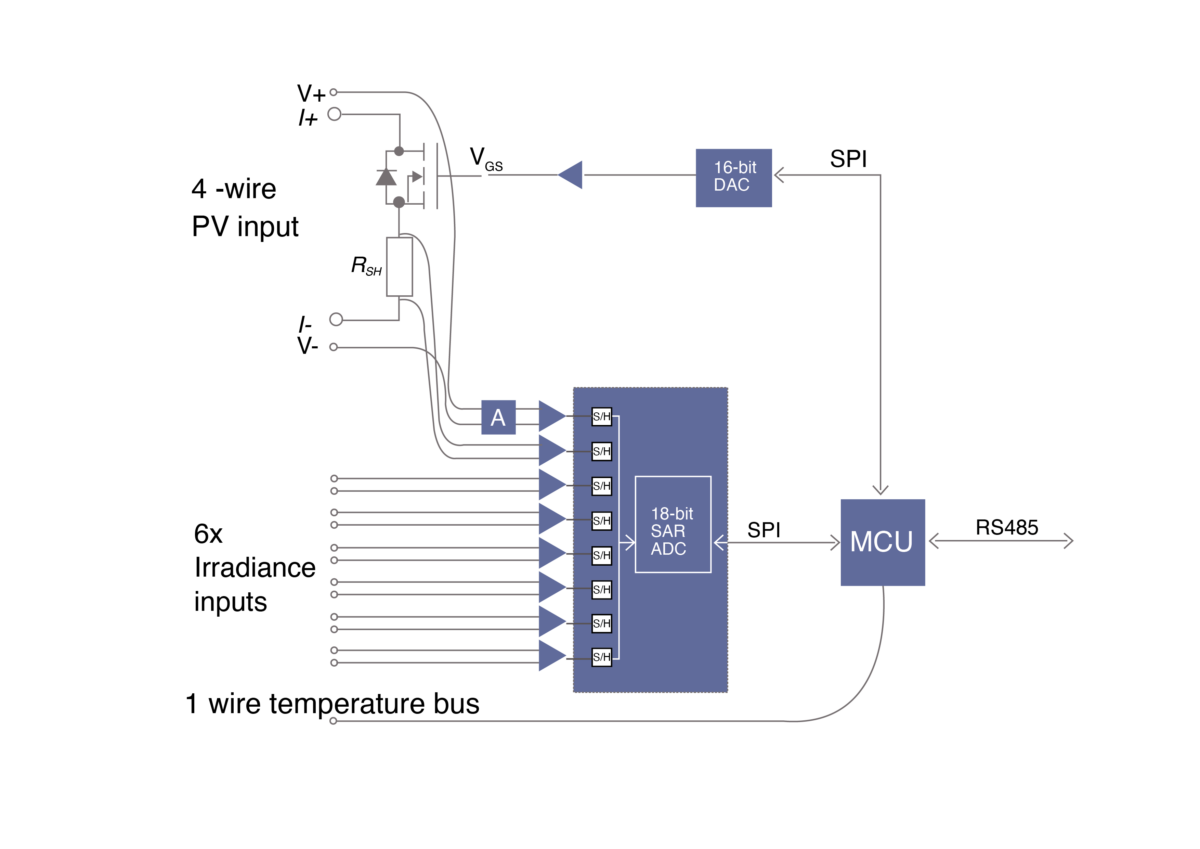

Schematic of the system

Image: pv magazine

Scientists from the University of Ljubljana in Slovenia have developed a monitoring system to estimate the effect of energy production on the driving range of vehicles hosting solar panels.

Dubbed PV measuring unit (PVMU), the monitoring system consists of an IV curve scanner that uses a MOSFET as a voltage-controlled electronic load. It utilizes an 18-bit analog-to-digital converter (ADC) and a microchip microcontroller (MCU), with the ADC being reportedly capable of the simultaneous sampling of 8 differential input channels at a sampling rate of up to 200 kHz.

A vehicle-integrated photovoltaic (VIPV) module can be connected to the electronic load in a 4-wire configuration. The current terminals are connected to the MOSFET, and the voltage sense voltage is adjusted to the range of the ADC by a resistor-based attenuator.

“The current is sensed using a high-precision shunt resistor (RSH) in a 4-wire Kelvin connection,” the research group explained. “Both resulting voltages are acquired by the first two differential ADC inputs. The remaining 6 input channels are used as general voltage inputs for irradiance sensors and are scanned simultaneously with the IV curve of the PV module.”

Moreover, the PVMU utilizes variable gain voltage amplifiers to adjust the input signal range to the input range of the ADC and a 1-wire communication bus to detect external digital temperatures. “The whole device is controlled via an RS485 bus from a personal computer, which is used for display, storage, and analysis,” the academics added.

The system was tested in a 192.4 W crystalline PV module mounted to the top of the Tesla Model 3 electric vehicle using the car roof rack system. All data from the PVMU were stored in real-time in an application-specific MySQL database, with different driving scenarios being tested under different environments and weather conditions.

“The car was used normally in every day 15 km commuting drives during working days from a home in the countryside to the Faculty of Electrical Engineering, University of Ljubljana (ULFE) and back, parked in an open parking space at ULFE during most of the day, and in the late afternoon, driven home and parked in a covered parking space,” the academics said, noting that they tried to make use of the car in a normal, daily manner. “Occasionally, we went for some longer drives, partially on a highway, parked in covered parking spaces and garages, and took some family trips during the weekends.”

The 2-month testing showed that irradiance measurements are crucial from all relevant sides of the vehicle, and that only fast-response solar cell-based irradiance sensors are appropriate for these measurements.

“An irradiance sampling time of 1 second is sufficient to monitor the harvested energy from VIPV with a relative error below 0.1 % in any ordinary vehicle use,” the researchers said, noting that even during parking, partial shading can cause significant MPP variations on a 1 s time scale. “The same time period is also recommended between IV curve scans.”

The team said the tests indicated that VIPV cannot cover the energy needed for everyday driving, particularly in wintertime. “It turns out that the Tesla Model 3 itself consumes around 200 W during driving and in standby with sentry mode on to power sensors, cameras, security systems, auxiliary power, and the mainframe computer,” it further explained. “This consumption is comparable to the baseline consumption of an average household, and it alone is challenging to be powered solely from VIPV.”

Their findings can be found in the study “Monitoring solar irradiance and PV module performance in mobile applications,” published in Solar Energy Materials and Solar Cells.

Events List of SNEC:

Date & Venue: Nov. 25-27, 2024, Shanghai New International EXPO Center (SNIEC)

- SNEC 9th (2024) International Energy Storage Conference & Exhibition

- SNEC 7th (2024) International Hydrogen and Fuel Cell Conference

Dates & Venue: June 11-13, 2025 National Exhibition & Convention Center (NECC)

- SNEC 18th (2025) International Photovoltaic Power Conference & Exhibition in Shanghai

Dates and Venue: March 5 – 7, 2025. Expo Guadalajara, Jalisco, México

- RE+ MEXICO 2025

Contact: Andy Chen Mobile & WeChat: +86-13816452416 Emai:wf.chen@snec.org.cn